AIRPULL INTERNATIONAL INDUSTRIAL CO.,LTD

THE DANGERS OF NOT REPLACING SCREW AIR COMPRESSOR FILTER ELEMENTS FOR LONG PERIODS OF TIME

The three filters of a screw air compressor include an oil-gas separator (oil-gas separation core), an air filter element, and an oil filter element. Failure to replace these filters over a long period of time can cause the air compressor head to seize up mechanically, seriously affecting its service life. The specific hazards are as follows:

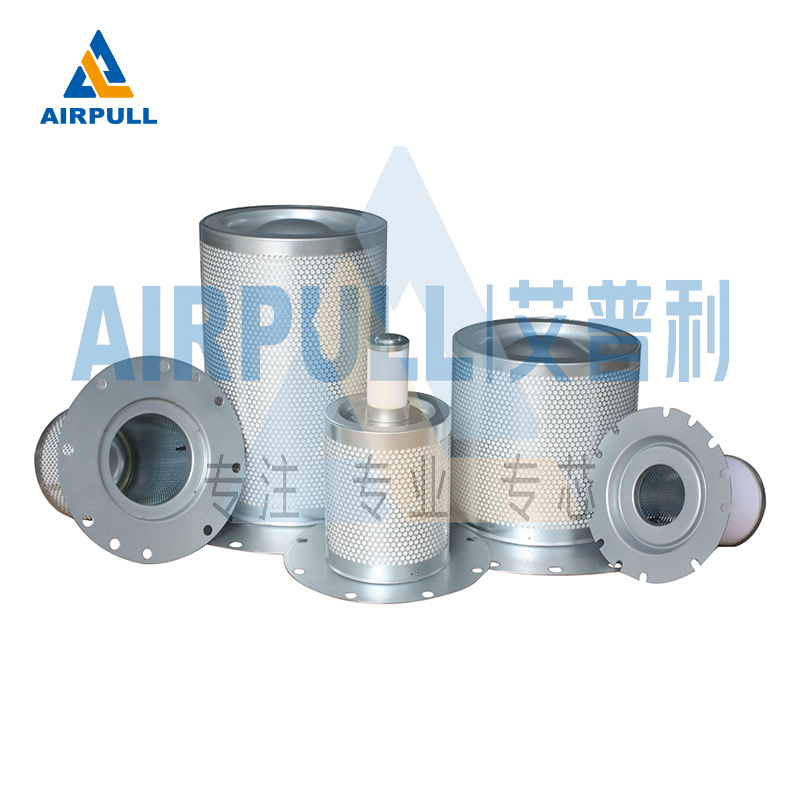

1. Air filter element

Excessive resistance in the air filter element increases the energy consumption of the air compressor.

The actual compression ratio of the air compressor increases, resulting in increased load and reduced service life.

Damage to the air filter element allows foreign objects to enter the main unit, causing it to seize up or even become unusable.

2. Oil-gas separation core

Reduced oil-gas separation efficiency leads to increased oil consumption, and severe oil shortages may even cause main engine failure;

Increased oil content at the outlet affects the operation of purification equipment, causing gas-using equipment to malfunction;

Blockages increase resistance, causing the actual exhaust pressure of the unit to increase and increasing energy consumption;

Fibreglass material falls into the oil, shortening the life of the oil filter element and causing abnormal wear on the air compressor.

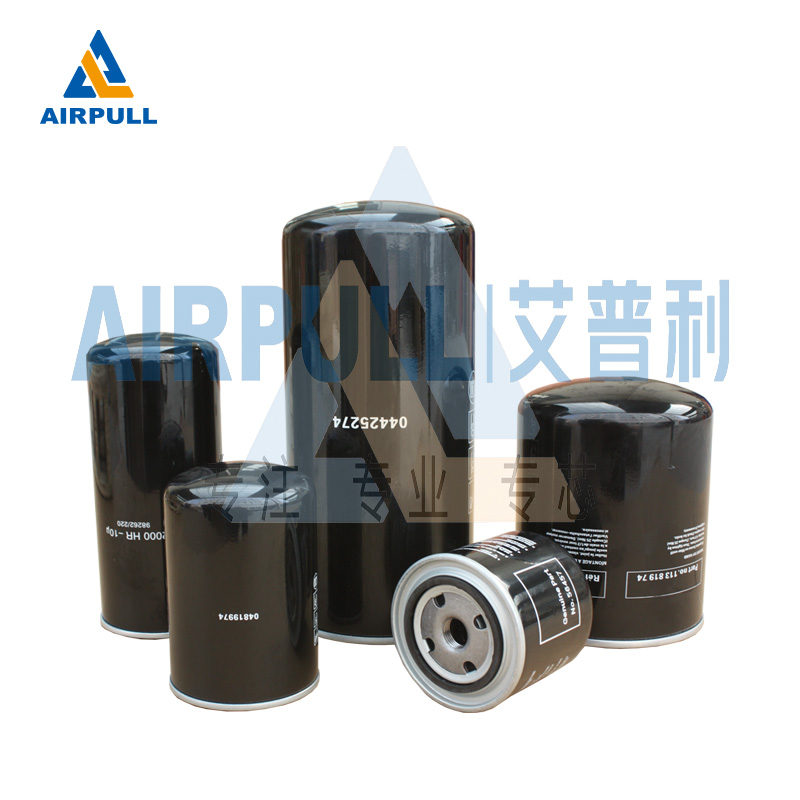

3. Oil filter element

Insufficient return oil flow causes excessive exhaust temperature, shortening the service life of the oil and oil filter element;

Insufficient lubrication of the main unit severely shortens its service life;

After the oil filter element is damaged, unfiltered oil containing a large amount of metal particles and impurities enters the main unit, causing severe damage to the main unit.

Aipuli is committed to producing the highest quality products as a professional manufacturer of air compressor three-filter systems. Our top-notch products and services ensure you can purchase with confidence and use with peace of mind.