AIRPULL INTERNATIONAL INDUSTRIAL CO.,LTD

Functions and Selection Criteria for Air Compressor Lubricating Oil

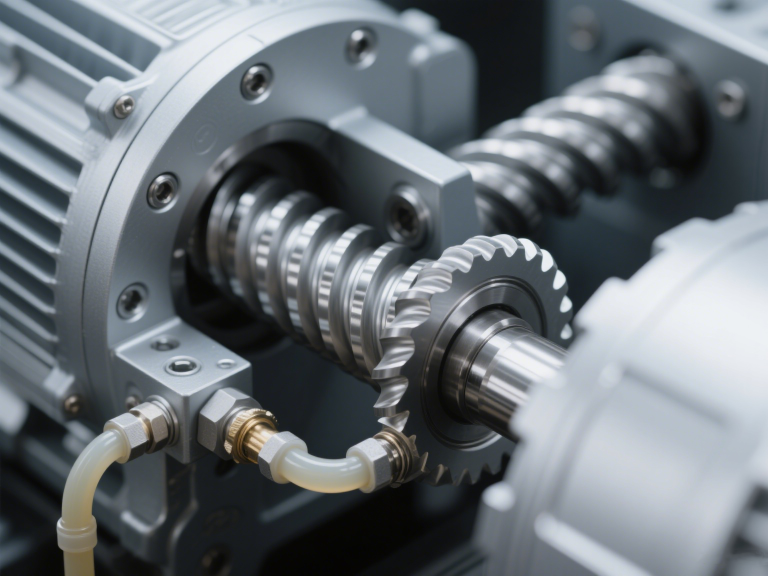

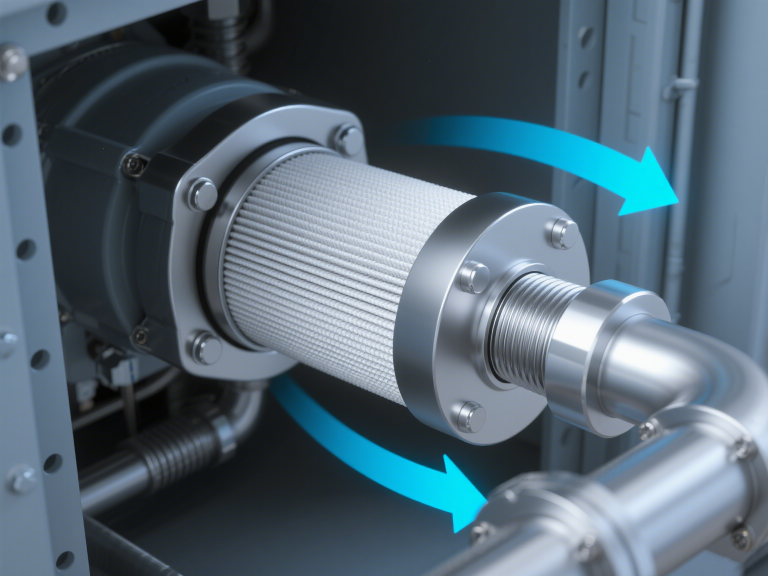

Air compressor oil is primarily used to lubricate the moving parts of compressor cylinders and exhaust valves, while also providing rust prevention, corrosion protection, sealing, and cooling functions. Since air compressors operate continuously under high-pressure, high-temperature conditions with condensation present, the oil must exhibit excellent high-temperature oxidation stability, low carbon deposit tendency, appropriate viscosity and viscosity-temperature characteristics, as well as superior water separation properties and rust/corrosion resistance.

I. Performance Requirements

1. Base Oil Quality Must Be Superior

Compressor oils are categorized into mineral-based and synthetic base oils. The quality of the base oil directly determines the performance of the finished oil (base oil typically accounts for over 95% of the finished product), and base oil quality is closely related to the degree of refining — — Higher refining depth results in lower heavy aromatics and gum content, reduced carbon residue, and improved additive responsiveness. This leads to reduced carbon deposit tendency in compressor systems, superior oil-water separation, and extended service life.

Mineral-based oils: Production typically involves refining base oils through processes like solvent refining, solvent dewaxing, hydrogenation, or clay supplementary refining, followed by blending with multiple additives.

Synthetic-based oils: Manufactured using chemically synthesized organic liquid base oils as raw materials, blended or enhanced with various additives. These base oils are predominantly polymers or high-molecular-weight organic compounds. Currently, synthetic oils used for compressor lubrication primarily include five categories: synthetic hydrocarbons (poly-α-olefins), organic esters (diesters), SNOT lubricants, polyalkylene glycols, fluorinated silicone oils, and phosphate esters. Although synthetic compressor oils are significantly more expensive than mineral oils, they offer superior overall economic benefits: strong oxidation stability, low carbon deposit tendency, lubrication capability in temperature ranges beyond the tolerance of conventional mineral oils, extended service life, and the ability to meet demanding operational requirements.

2. Base Oil Fractions Must Be Narrow

Analysis of air compressor operating conditions reveals that the fraction composition of base oil is a critical factor affecting compressor oil quality. Using oils with broad fractions—a mixture of light and heavy components—introduces two major issues when injected into compressor cylinders: Light fractions, due to excessive volatility, readily separate from working surfaces prematurely, diminishing lubrication effectiveness; Heavier fractions, with low volatility, struggle to exit the working area after completing lubrication tasks. Prolonged exposure to high temperatures and oxygen promotes carbon deposit formation. Therefore, compressor oils should utilize narrow-distillation-range oils rather than multi-distillation-range blends.

For example, Compressor Oil No. 19, formulated with a wide-range base oil containing substantial residual components, exhibits significantly elevated carbon deposits during operation. To enhance its quality, residual components must be removed, and a narrow-range base oil should be substituted.

3. Viscosity Must Be Appropriate

From the perspective of dynamic lubrication principles, oil film thickness increases with rising oil viscosity, but friction also intensifies accordingly. Therefore, viscosity selection is the core consideration in choosing compressor oil:

Too low viscosity: Insufficient oil film strength may form, accelerating component wear and shortening service life;

Too high viscosity: Increases internal friction, raising the compressor’s specific power consumption. This leads to higher energy and oil consumption while potentially causing deposits in piston ring grooves, valves, and discharge passages.